Loving Leitz

Creative Homes Scotland has benefited from innovative tooling solutions that have streamlined its manufacturing processes, reduced its costs and enhanced the quality of its furniture.

Glenrothes-based Creative Homes Scotland designs, manufactures and installs high quality and bespoke furniture across Scotland. The company, a recent entrant to the industry, has been working closely with Leitz Tooling to develop the business, streamline manufacturing and ensure top quality products. Owner and director, Alan Goodsir has developed a close relationship with Leitz over the last three years and confirms Leitz was able to offer meaningful recommendations and setup support that helped the business to get started:

“Steven from Leitz offered us valuable tooling advice and he worked closely with our machinery supplier to get us set up with the correct tooling, including recommendations on cutting speeds and RPM’s. Leitz also introduced us to a system to avoid downtime and ensure there is always a tool on the machine, one ready for use and another tool off for sharpening. We don’t have to worry about the tooling side of the business any more.”

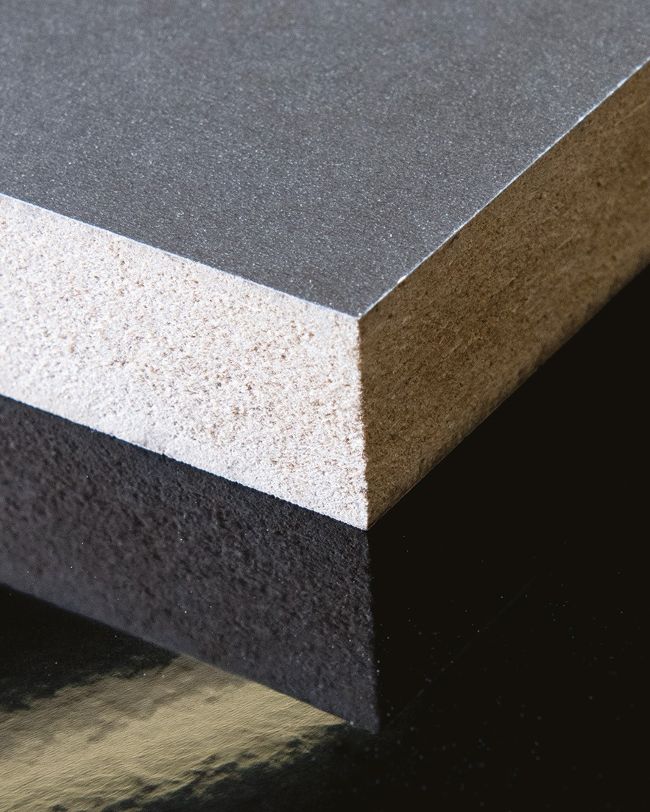

Once Alan had set up his machine shop and processes, Leitz continued to support Creative Homes by offering innovative tooling solutions that addressed challenges in production as they arose. As part of their kitchen offer, Creative Homes manufactures kitchen worksurfaces with Krion ® solid surface. Like many solid surface materials, Krion ® can be difficult to machine due to its composition and properties. Its non-porous nature can cause excessive heat build-up when machining, which can lead to melting of the material, excessive tool wear and chatter or burn marks.To solve the challenges, Leitz Tooling introduced Creative Homes to the BrillianceCut sawblade.

BrillianceCut sawblade

Diamaster Pro3

Featuring a pioneering tooth geometry, the BrillianceCut achieves excellent cutting results even in polymer-bound mineral materials such as Krion ® .The tooth geometry ensures finish cut quality and breakout-free cutting, even on tough materials. Alan commented that, “The new blades cut through material like butter, with much less wastage and no chipping. Doing it right the first time has been invaluable.” Higher quality finishes lead to huge cost and time savings, eliminating rework. With up to 20 sharpens, the BrillianceCut offers a sustainable and very economical solution to solid surface and plastic sawing.

After noticing an increase in tool wear, breakage and damage; Leitz recommended that Alan swap Leitz UK-made carbide spiral router cutters for Diamaster Pro3 diamond nesting routers. The Real Z3 design cuts up to 50% faster than standard diamond routers, allowing for reduced cycle times and increased efficiency, while gullets in the tool body support efficient chip extraction and avoid resin build up on the cutting edge.

“Introducing the Leitz PCD routers on our CNC has had a positive impact on quality thanks to greatly reduced chipping. The finish quality also means we get better cuts when edgebanding.” Additionally, using Diamaster has resulted in a massive decrease in sharpening costs as the tools can be sharpened multiple times and used for longer.

To improve the efficiency and tool life even further, Creative Homes mount their Diamaster router cutters in the ThermoGrip heat shrink chuck. The ThermoGrip clamping system combines the tool and chuck into one tool body through thermal shrinking. It plays a decisive, yet often overlooked role in the machining process as its stress-resistant body can help achieve up to 50% higher feed rates compared with collet chucks. With a higher clamping force that is six times greater than conventional collet chucks. The ThermoGrip’s perfectly-balanced geometry reduces vibrations, noise and tool wear.

This vibration-reducing technology extends the life of mounted tools by up to three times and supports up to 36,000rpm for high performance cutting – faster than most machinery. Leitz measures tooling to three decimal points for height and diameter. This accuracy assists setting up and to aid the tool life, test cuts are not required. The small “nose” of the ThermoGrip chuck supports efficient extraction and chip removal.

Creative Homes has also benefitted from the Leitz tool service programme. The sharpening service has addressed many manufacturing challenges faced in the factory and ensured the company’s tooling is cost-effective and operating at maximum performance. The sharpening service extends tool life while improving cutting performance, making tooling more efficient, sustainable and helping to maintain reliable cycle times and a consistent finish quality. Leitz has eight service centres in key locations across the UK for tool sharpening and repair, and with the UK’s most sophisticated saw sharpening setup, it is uniquely positioned to support Creative Homes as a sole supplier. Leitz sharpening services are accurate to microns and the intricate sharpening process revitalises tools so they perform at their best, offering a consistent finish quality. “The support given is above everyone else,” says Alan, “Even setting expectations on tool life.”

Overall, support from Leitz has enabled Creative Homes to stay focused on what it does best: manufacturing high quality kitchens, bedrooms and bathrooms. The significant transformation has at least in part been the result of its strategic partnership with Leitz Tooling and Alan freely admits, “Leitz are the best at what they do, that’s why we have developed a great working relationship.”

For more information on the innovative tooling solutions and expert sharpening services provided by Leitz, streamline your manufacturing processes, reduce your costs and enhance the quality of your furniture, call 01279 454530, visit www.leitz.org or email Contact-uk@leitz.org